Inspecting Cylinders – Beyond the Hydro

by Don Kinney

Scuba diving organizations, being aware of these hazards, encourage annual visual inspections of cylinders. The National Fire Protection Association (NFPA) 1852 (7.1.2.4) requires an inspection of the cylinder at the beginning of each duty period. The Occupational and Safety Health Administration (OSHA) requires that each employer ensures that gas cylinders are safe, which can be determined by a visual inspection (1910.101(a)). None of these rules or regulations explain what to look for during these visual inspections. How can a person know what conditions are considered a safety risk?

A proper high pressure cylinder visual inspection course will show a user/inspector what conditions are acceptable and what conditions could be dangerous. The course also helps guide the user/inspector on what the next steps are to ensure safety. Each type of cylinder has unique characteristics which must be monitored to ensure its structural integrity.

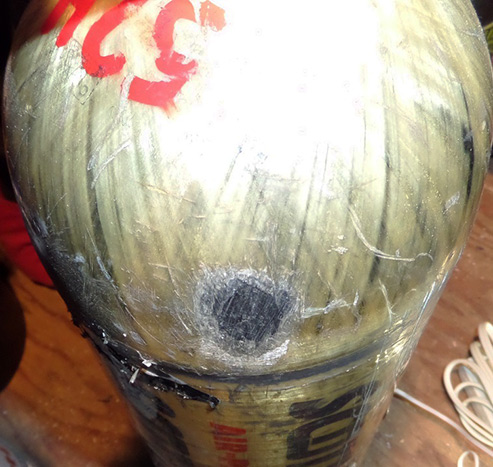

Composite cylinders are light weight and handle greater pressures than their solid metal counterparts, but that does not mean that they can handle the same type of environment or abuses. Users/inspectors must pay close attention to cuts and gouges, as even a small cut can render the cylinder condemnable. They also respond differently to impact damage, which might not be easy to detect without proper training. These cylinders also are highly susceptible to chemical exposure and a minor incident involving a chemical might condemn a composite cylinder.

Cylinders are exposed to extreme conditions on a regular basis, thus it is recommended that they are inspected more frequently than every five years. Some of these exposures may make a cylinder unsafe long before it is due for it’s next hydrostatic requalification. A cylinder inspection course will train the user/inspector on the unique characteristics of each type of cylinder and how to recognize potential dangers before they become dangerous hazards.

Don Kinney

High Pressure Cylinder Inspecting Instructor

댓글을 남겨주세요

토론에 참여하시겠어요?언제든지 참여하세요!