If you own tanks and intend to use them for Nitrox diving (and you should!) there are a couple of things you need to do before filling them with your personal mix.

The Blending Method Counts: SDI dive centers, resorts, and live aboards employ a variety of methods to create Nitrox, including partial-pressure blending in dive cylinders and storage bottles, continuous-blending systems and separation membranes.

Whether or not to O2 clean other equipment items is dictated by a hierarchy of practices.

- Local laws, regulations and standards of practice always take precedence over any less-strict requirements.

- Manufacturer’s specifications also take precedence over any less-strict requirements, as dive operators cannot defend a decision based on the fact they presume to “know better” than the engineers who designed a particular piece of equipment.

- Absent the precedence of either of these two factors, the standard of practice is to apply what is known as the 40 Percent Rule.

The 40 Percent Rule

In essence, the 40 Percent Rule states that, if a regulator, cylinder or valve will not be exposed to gas mixtures with an FO2 greater than 40 percent, at pressures greater than regulator intermediate pressure, they need not be O2 clean or service rated.

The 40 Percent Rule is widely accepted by divers, dive operators and government agencies. Nevertheless, some manufacturers specify that any regulators, cylinders or valves exposed to gas mixtures other than air be O2 clean and service rated. It’s not a bad idea to ensure that any cylinder designated for Nitrox use be kept O2 clean and service rated as well, regardless of whether it will be filled using partial-pressure blending or not.

Oxygen Compatible Air

- Standard scuba air — although very clean and dry — still contains trace amounts of hydrocarbons and other contaminants. If allowed to collect on the internal surfaces of cylinders, regulators and valves, these create a risk of fire and/or explosion — a risk that O2 cleaning will eliminate.

- Oxygen-compatible air, on the other hand, is virtually free of hydrocarbons and contaminants. By making certain that the internal surfaces of cylinders, regulators and valves only come in contact with oxygen-compatible air, or gas mixtures created using oxygen-compatible air, you effectively eliminate the risk of fire or explosion, and maintain your equipment’s O2 service rating.

- Only allow this equipment to come in contact with oxygen-compatible air or gas mixtures, or…

- …if the equipment does come in contact with standard scuba air, to remove any markings that indicate it is O2 clean, and not represent to dive operators that any such cylinders are suitable to be filled with Nitrox through in-cylinder partial-pressure blending.

Nitrox divers often have their cylinders refilled with air for dives in which having Nitrox may not offer any appreciable benefit. If you do so, and if your cylinder is O2 service rated, you must use only oxygen compatible air.

Tank Marking and Identification

Any time you fill a tank with Nitrox, it must be identified as such. This will help to prevent accidents in the event that someone uses a tank filled with Nitrox without taking the proper precautions. The industry standard for tanks filled with Nitrox is to mark the tank with both a tank wrap, as well as to identify the mixture with a label or tag.

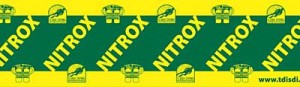

A Nitrox tank wrap is an adhesive decal, generally 10-13 cm/4-5 in in width, that is designed to completely encircle the diameter of the tank. The tape is usually printed in yellow with the word Enriched Air and/or Nitrox printed continuously on it in bold green letters. This tape makes it quick and easy to spot a Nitrox bottle in a group of tanks.

Any tank used for Nitrox diving must also have a tag or label attached to it where the exact Nitrox mixture used in the tank (FO2) and its MOD can be read. Some shops use plastic tags that can be written on and reused, some use labels stuck to the tank itself, others use duct tape stuck to the cylinder neck. It doesn’t matter which style of marking device is used, as long as the information is instantly available on the tank.